NDT Terminology

|

|

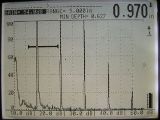

Ultrasonic Testing

In ultrasonic testing, ultra-high

frequency sound waves are transmitted into a material to

detect imperfections within the material, or changes in

material properties. The pulse echo technique is

accomplished by introducing sound into the test object and

reflections (echoes) are returned to a receiver from

internal imperfections or from geometrical surfaces of the

part. It is typically used to detect subsurface defects, or

defects originating from surfaces not accessible without

disassembly or removal. It can also be used to detect

laminations, lack of fusion, and corrosion of various

materials.

|

|

|

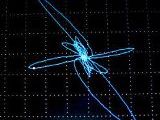

Eddy Current

With the eddy current method, electrical currents are generated into

a conductive material by an induced, varying magnetic field.

Imperfections or changes in a materialís conductive properties cause

interruptions in the flow of these electrical (eddy) currents. This

results in changes in the induced magnetic field, which is

monitored, and indicates the presence of a change in the test

object. The eddy current method is used extensively to inspect

aircraft skin and structure for very small surface breaking flaws

and can successfully detect sub-surface discontinuities. This

methodology is also used in the sorting of metal alloys as well as

precisely determining the thickness of various coatings.

|

|

|

Visual Inspection

The oldest and most common method of NDT, visual examination has

numerous applications. It has even been traced back to the book of

Genesis! Visual techniques are used in conjunction with all other

NDT methods, but may be used as the primary inspection method. The

inspection of a turbine engine hot section using flexible or rigid

borescopes is an example of the visual testing method.

|

|

|

Magnetic Particle

Magnetic Particle inspection is conducted on ferro-magnetic material

by inducing a magnetic field into the test part and coating the

surface with iron particles (either dry or suspended in a liquid).

Surface imperfections will distort the magnetic field causing an

accumulation of the iron particles near imperfections, thus

indicating their presence.

|

|

|

Liquid Penetrant

Liquid penetrant inspections are only able to detect surface

breaking flaws.

The specimen is coated with a fluorescent or visible dye solution.

After a specified dwell time, the excess penetrant is removed from

the surface. Often, a developer is applied to help draw penetrant

out of imperfections open to the surface, making them much more

visible. With fluorescent penetrants, an ultraviolet lamp causes the

indications to fluoresce brightly, greatly increasing the visibility

of the flaw. Liquid penetrant inspections are only able to detect

surface breaking flaws.

|

|

|

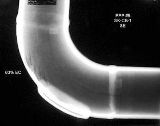

Radiography

An X-ray machine, or radioactive isotope is used as a source of

radiation. The radiation is directed through the test part and onto

a recording media (often film). When the film is developed, a

radiograph is obtained that can show the internal condition of a

part. Possible imperfections show up as density changes (a

difference in blackening between two adjacent areas) in the film.

Cracks, porosity, lack of fusion and tungsten inclusions in welds

are but a few of the examples of possible flaws that may be

revealed.

|

|